for Complex Wood Projects

for Complex Wood Projects

for Complex Wood Projects

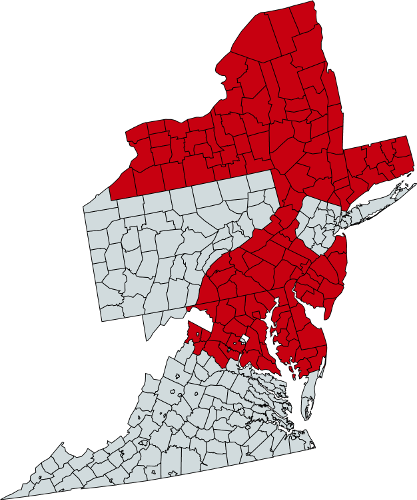

American Pride Builders is a large commercial wood framing contractor with a goal of providing a superior product and complete customer satisfaction. A family owned and operated company, American Pride is a one-stop solution for high quality framing systems. We offer Pre-construction Services such as design and value engineering, and efficient production through our sister company, Building Solutions. Our job-site supervision by experienced, qualified foremen keeps projects on schedule and within budgets. We service a wide area in the Northeast and Mid Atlantic states including PA, MD, VA, DE, NJ, NY, and CT.

We own and operate co-located, autonomous businesses that work in concert to create very strong value to our professional clientele.

Our family owned and operated companies are highly specialized, wood based pre-fabrication manufacturers and turnkey framing contractors. We are exclusively focused on large scale commercial projects in the multi-family, hospitality, student housing, independent living and continuing care retirement sectors.

American Pride Builders is a full-service framing operation with well-trained teams of Project Managers, Assistant Project Managers, and Material Management Specialists. Our crews are highly skilled and are current in all OSHA certification training.

Buildings Solutions Since 1977, LLC is a full-service design, build, value engineering fabricator with engineering and pre-construction services departments. Our 138,000-square foot fabrication facility has an annual production capacity of 2 million square feet. We have a very cost effective raw material procurement process, fully supported by on site covered storage. We have a fleet of corporately owned tractor and trailers that enable us to support aggressive project schedules.

Our process saves significant and valuable time as we produce the engineered framing system concurrent with the foundation and under slab utilities under construction in the field. We are able to work in a controlled environment, minimizing the weather delays commonly imposed on a project.

Material is stored in a controlled environment longer, thereby reducing your exposure to mold and mildew, warping, or other quality issues. We are able to work faster, smarter and safer, reducing your construction cycle time and facilitate a timely and successful completion of your project.

At the outset of each project, we will develop a detailed task-by-task duration schedule on a floor-by-floor, building-by-building basis.

We take Quality Control seriously and have developed and implemented a very refined process. Our multi stage, layered inspection and certification process results in the best product possible.

We routinely value engineer projects to reduce cost, improve performance and reduce field labor and cycle time using state of the art software applications. We are able to provide and check structural calculations, material usage, and make sure that everything fits perfectly. Detailed shop drawings are drawn and submitted for approval. Once approved, each order is electronically submitted to our automated machinery and assembly stations where lumber is optimized. By assembling the trusses and panels in a factory setting, we provide a safer, more efficient process for our workers, which results in a better product for you.

Our family of companies owns and operates a full scale state-of-the-art roof, floor truss and panel plant. Fully supported by our in-house engineering department, corporate owned and operated fleet of trucks and trailers, we can directly control each and every aspect of the entire process.

We have developed and refined all the operating procedures and have built and trained teams of project managers, quality control inspectors and material management specialists to properly plan and manage a wide variety of the logistic issues necessary to complete your project on time and on budget.

Our experienced team strives to complete every project on time and on budget, however our main product is relationships. Our experienced team members partner with our clients to meet their overall strategic objectives. We routinely coordinate with MEP contractors to facilitate timely execution of each project, meet our own quality control standards and support the project management team in every way possible.

Over the years, IMC has completed several projects with American Pride Builders. We work with American Pride Builders because of their ability to provide a one-stop solution for supply and installation of wood framing, and their detailed pre-construction process identifying conflicts and issues. American Pride’s integration with their pre-manufactured wood panel supplier allows our projects to move quickly once framing begins. A lot of the necessary QC and coordination is completed during the shop drawing process for the manufactured panels, allowing us to focus on production and safety once the project began, not RFIs and layout issues. American Pride’s commitment to safety fits well with our CCIP program and our enhanced focus on providing a safe working environment for all of our subcontractors. I would recommend American Pride Builders to any Owner or General Contractor in need of a framing contractor capable of providing pre-construction services, as well as providing a quality product in a safe and productive manner.

I have worked with the team at American Pride Builders for many years. They have consistently delivered above and beyond my expectations

"Quality at a reasonable cost" has always been the sales statement in the construction market place along with "On time, on budget". You could pick any two, either speed, quality or cost but never all three. The methods used in American Pride Builder's process now ensure all three can be achieved. Combining construction elements into a complete wall system constructed in a controlled environment and shipped directly to the site reduces greatly the amount of time needed to enclose a building and increases the quality of the building's shell. Now its possible "On Time, On Budget, High Quality!"

Our company is very well versed on the National Green Building Program, in fact, our president helped to create the program itself and establish many industry relationships.

Because green is in our DNA, most of what we do is green by its very nature. From designs and process that minimize waste, to efficient working conditions, not only do we automatically qualify your project for 101 bonus points, we help your bottom line as well.